Automation today has become a race for all manufacturing businesses. Applying automation in production helps increase business competitiveness, save time, reduce waste of resources and resources, reduce costs, and increase product accuracy. To start investing in production automation processes, businesses first need to understand the following notes.

1. Is automation right for my business?

Automation brings many benefits to businesses. But to make a decision to apply it to the factory’s production line, businesses need to consider the impact of this automatic process to help the business improve, whether it is suitable for the business model and goals. business goals?

And most importantly, we need to consider the impact on personnel. Can they embrace automation technology positively? Can I receive training in knowledge and skills to work with the new system? Because in reality, many workers still have negative prejudices, considering robots as a threat to human jobs and are not equipped with necessary technology skills.

When determining the suitability of automation for a manufacturing factory, business leaders will be able to make accurate decisions and specific plans and strategies.

2. What processes is factory automation applied to?

Depending on different purposes, as well as the product and field of operation of the business, there will be suitable applications. Therefore, before starting automation, it is necessary to determine which process the application is for and evaluate its feasibility.

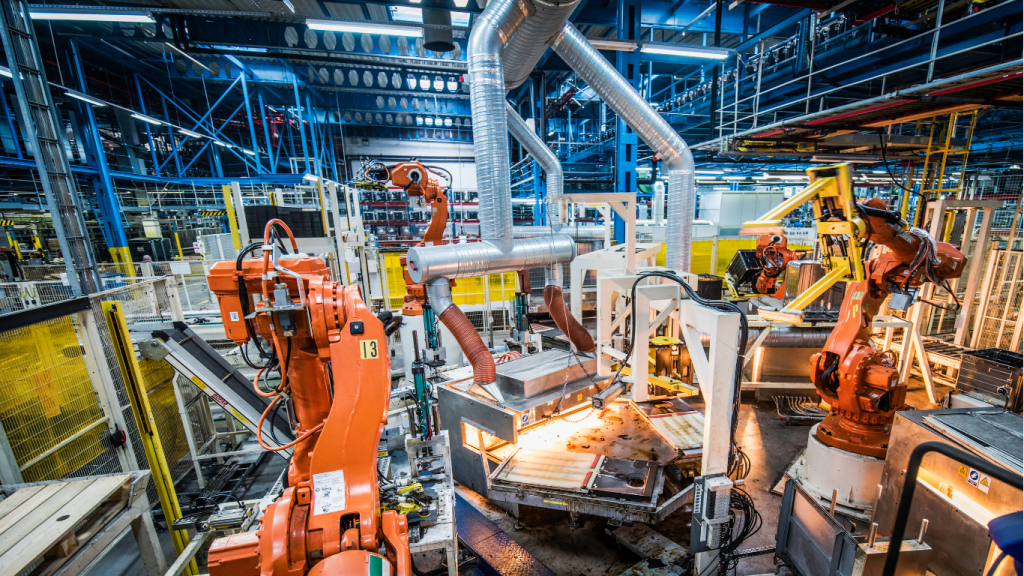

For example, businesses that produce electronic equipment will apply automation in material processing and quality inspection processes. Food and beverage manufacturing businesses mostly use robotic systems in packaging. Car manufacturing businesses work with specific automatic lines such as welding, painting, assembly, etc.

3. Resources needed to prepare for the application of automation to manufacturing plants

Investing in automation requires businesses to be prepared in terms of financial resources. It’s not just as simple as buying a product to use, automation involves the entire process of producing quality products. In addition to costs for robots, machinery, hardware equipment, and accompanying software programs, businesses also need to consider costs for repairs, maintenance, improvements, upgrades, etc.

In addition, this process also requires investment, restructuring and allocation of human resources. Instead of tasks being performed manually, with automation, people will combine with robots or humans to control, operate and program machines. Workers need to be equipped with the necessary knowledge and skills training to use and operate automation equipment effectively. To avoid errors, businesses need to apply automation gradually. In the beginning, you can use fewer types of machines to simplify use, allowing workers to gradually become familiar with the technology, thereby reducing the rate of problems and making troubleshooting easier. After a period of smooth operation, automatic synchronization can be applied.

A suggestion for businesses that are just starting to automate is to hire outside technical experts to train and improve the knowledge and skills of internal engineers. This is called on-site training service, often designed to provide training through experimental operation and maintenance right on the system and production line at the customer’s factory to bring the most practical results.

Primus Technology is a specialist in the field of production automation. We support businesses throughout the machine operation process. Contact now:

0964 658 958

4. Automate individual production lines or the entire production line at the same time?

Individual automation is a long-term task, requiring patience, performing each step properly. The result will be that your business processes are optimized thanks to automation applications. Progressive automation also reduces financial pressure on leaders, giving employees time to adapt to changes in work processes.

Automation can also be considered a form of master planning. This approach increases coordination between steps, reducing the amount of work needed to move small processes into the bigger picture. In the long term, this is a more beneficial choice for businesses. However, this form requires large investment capital and major changes in personnel and production processes. Therefore, the downside is that it is difficult for businesses to adapt immediately.

Above are the most basic factors that need to be considered before starting to automate a production factory. To be able to make the right decision, you can seek the help of experienced automation experts. With the mission “Our technology is your solution, Primus Technology not only designs and manufactures automation machines according to customer requirements but also advises on production improvement solutions, helping you customers solve difficult problems, cut costs, maximize profits.