WASTED CHIPS AND CUTTING OIL – LOSSES IN MACHINING

80% of Chip Storage Space Wasted

Expensive Cutting Oil Lost as It Mixes with Chips

Daily Labor Required for Chip Transportation

High Costs Due to Investment in Multiple Chip Containers

80% of Chip Storage Space Wasted

Expensive Cutting Oil Lost as It Mixes with Chips

Daily Labor Required for Chip Transportation

High Costs Due to Investment in Multiple Chip Containers

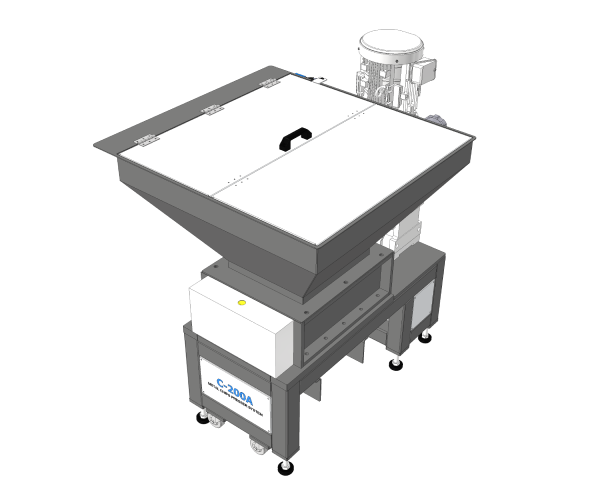

With a structure consisting of three main components assembled together, the machine is easy to install and use, making it suitable for various factory sizes.

REQUEST A QUOTE

Chip Cutting Machine

Conveyor Belt

Chip Briquetting Machine

TECHNICAL SPECIFICATIONS TABLE

| Model | BPS-45T System |

| Overall Dimensions | L 3,800 x D 1,1,45 x H 3,000 |

| Power Supply | 3-Phase 380V |

| Hydraulic Motor | 3.75 kw |

| Chip Briquette Diameter | Ø 75mm |

| Cycle Time for 1 Briquette | 28 s |

| Processing Capacity | 50~120 kg/h |

| Compaction Ratio | 20:01 |

Advanced Technology: Utilizes modern technology with an intelligent control system via PLC, making it easy to adjust parameters and compaction sizes.

User-Friendly Design: With a structure consisting of three main components, the machine can be easily installed and operated, suitable for various factory sizes.

Energy-Efficient: Saves electricity, operates smoothly, and efficiently